A look at Environmental Air System's off-site construction program

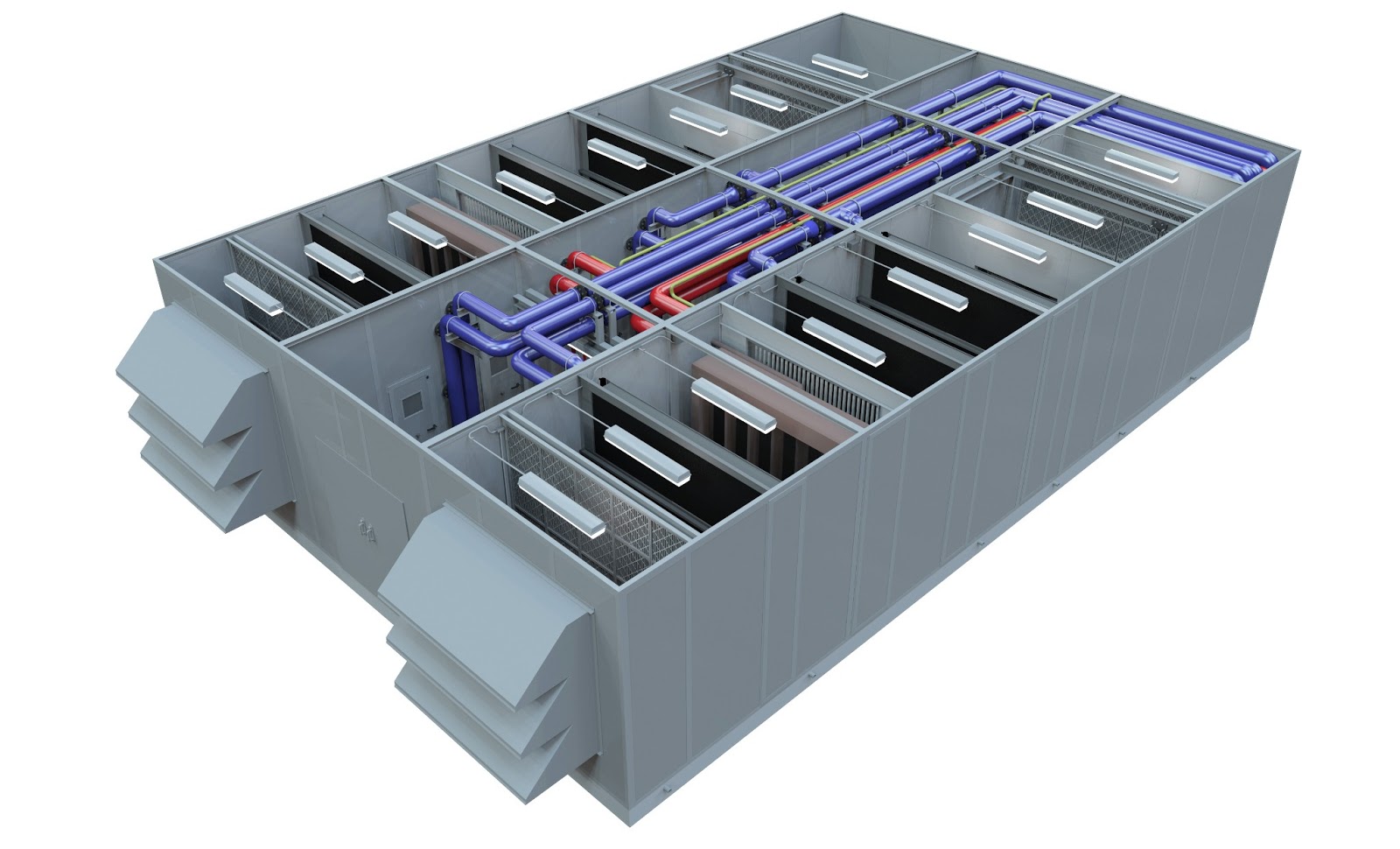

Environmental Air Systems (EAS) is a full service mechanical contractor based in North Carolina specializing in mechanical systems for health care, pharmaceutical, and data centers. EAS also has unique capabilities for Off-Site Construction (OSC), which allows for the manufacture of a wide range of products from mechanical skids and air handling units, to full central utility plants and large scale modular data centers.

With SketchUp Pro, Environmental Air Systems has been able to improve communication with their clients as well as increase their Off-Site Construction productivity. Carroll Shephard is the Production Design Coordinator for EAS, and also one of their SketchUp champions. He spoke with us about how EAS uses SketchUp.

SketchUp at EAS

Back in 2007, EAS was working on two data center projects. In an effort to create a more accurate and visual as-built of the product, we switched to SketchUp. We provided our client with an AutoCAD version along with the SketchUp as-built model. The client really liked that we gave them something more visually rich through SketchUp. Since then, we have transitioned all of our production drawings to SketchUp. Now, we are adding SketchUp to more processes than ever.

With SketchUp, we don’t spend a lot of time learning the software, and because it’s so intuitive, we’ve reached a point where we can rapidly turn detailed models into coordinated production drawings for our manufacturing facilities. Then, we generate material lists with an extension plugin.

The use of 3rd party plugins, like Space Design by RenderPlus, allows for custom report generation directly out of SketchUp

The use of 3rd party plugins, like Space Design by RenderPlus, allows for custom report generation directly out of SketchUp

SketchUp has changed the way we design as it enables us to transition from 2D to 3D. The advantage of working in 3D is that our product is “virtually built” before materials are ever ordered. Previously, we coordinated parts by calculating the clearances needed using a calculator or spreadsheet. Now, all the drawings (previously made using AutoCAD) are produced in SketchUp. From there, we have been able to coordinate our products using Navisworks (and we’re now experimenting with Tekla BIMSight).

SketchUp Pro & Client Communication

While communicating with clients, SketchUp most often plays the role of a visual aid. For example, we recently worked on the preliminary design of a pipe rack system to be installed in a pharmaceutical facility. With SketchUp, we were able to model the pipe rack exactly as it would be installed (a retrofit situation). The SketchUp model helped the marketing group clearly communicate the scope of work and make sure that our design was meeting or exceeding client expectations.

We also generate concept renderings for potential clients. These allow our clients to see what their project will look like once completed. So to a real extent, we also use SketchUp as both a sales and design-build tool: it enables us to show potential clients our solution for their specific application and then it helps us produce accurate, detailed drawings quickly. Both of these advantages enable us to be more successful and it has been a driving force on many projects.